Our artificial intelligence enhances quality in the automotive industry.

Artificial intelligence analyzing images has various applications, including its implementation in the automotive industry. Upon the request of AURES Sp. z o.o. from Sosnowiec, we developed a workstation employing artificial intelligence to assist in maintaining the quality of packing elements.

By employing a tracking camera to monitor the packer’s movements, the workstation can verify whether the packed element is placed in the correct packaging. Previously, human error occasionally occurred. Currently, the workstation triggers an audible and visual alarm when the packer makes a mistake, alerting them to the potential error. Additionally, the workstation has been equipped with QR code readers, as the produced parts are marked with these codes. The readers verify the accuracy and readability of the QR codes.

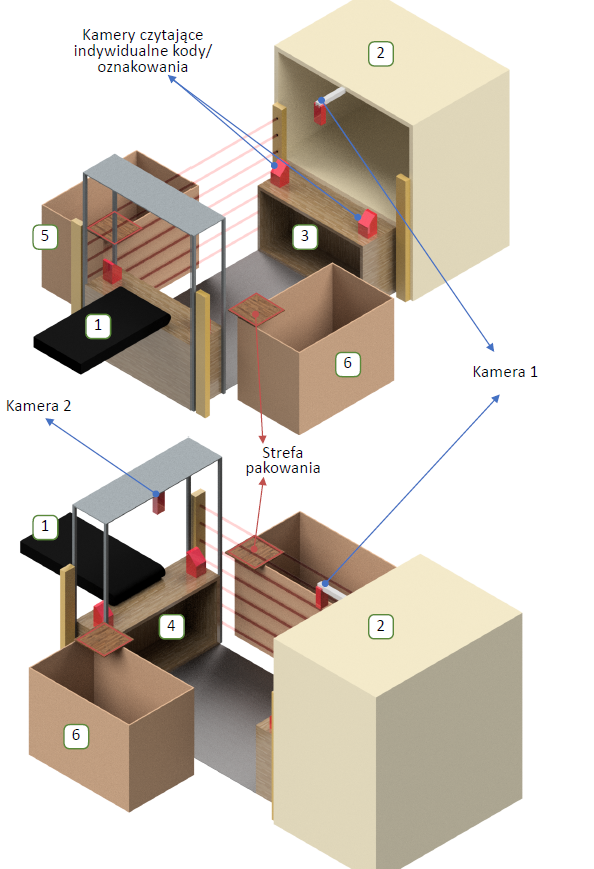

The operational model of the workstation is depicted in the diagram below:

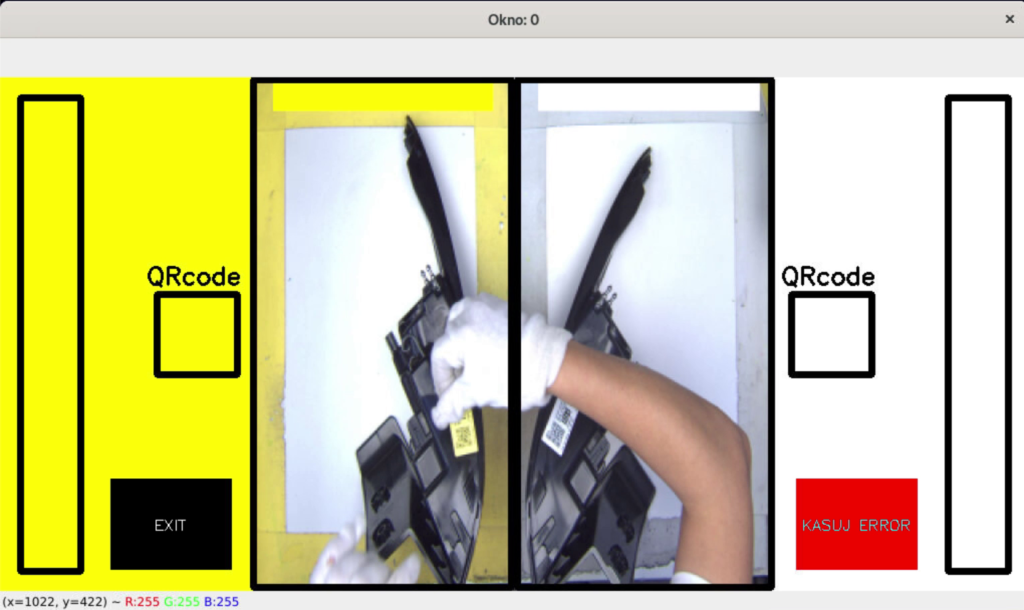

The actual workstation was developed based on the model. Below is a simple user interface along with an image during the system’s operation. The image contains information about the recognized element, confirms the correctness of the packer’s actions, and provides details about the type of error made:

“In the next picture, you can see that the system correctly identified the removed element and confirmed the accuracy of reading the QR code:

The application has been operational at the client’s site for several months. Tests have confirmed its proper functioning and effectiveness in error elimination.

If you would like to know more, feel free to contact us at: biuro@pumaa.tech